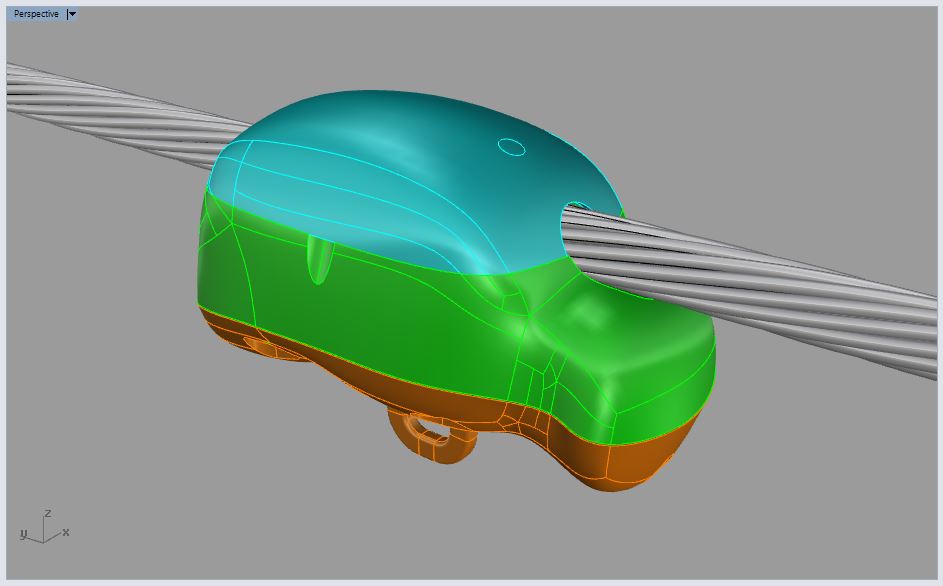

A good example involving high-requirements functional prototyping is a powerline monitor system designed for Maple Microsystems in Ottawa. Right from the beginning there was already a clear vision for the final looks: the silhouette of the final concept should evoke a bee. Once deployed, these overhead devices are quite visible since they are clamped around powerlines and the lump easily catches the eye. The bee shape provided some natural harmony to the inevitable visual disturbance, while it cleverly distinguished MapleBee from the competition in the blink of an eye.

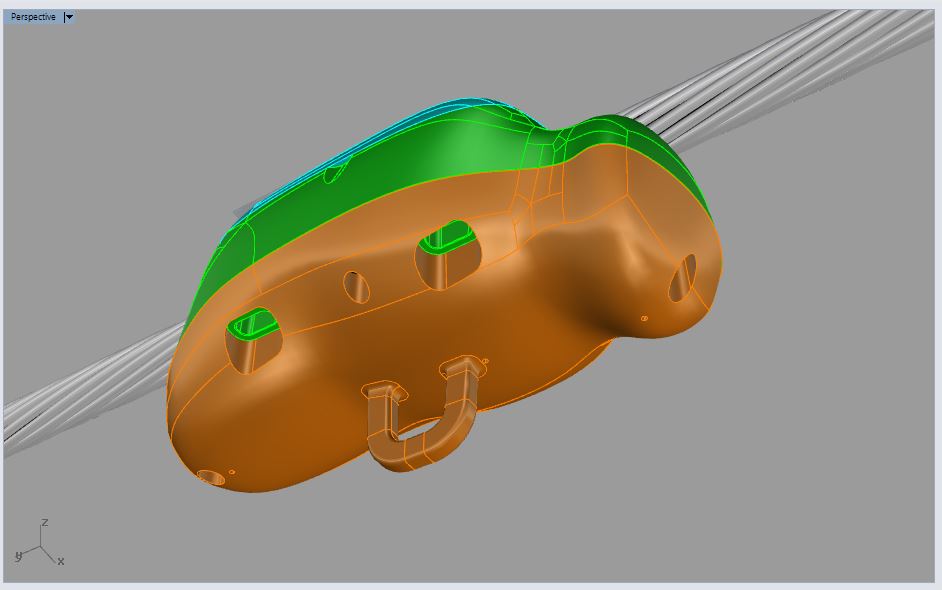

The mechanical requirements also provided an interesting challenge: the clamping system inside the wings of the bee would have to adapt to a wide range of cable diameters. It had to include an induction clamp, a temperature probe and all that had to resist the wide range of weather conditions Ottawa can go through in a full seasonal cycle. The strength of the clamp mechanism had to keep the thing up there no matter how strong the wind, yet allow the device to be pulled off and pushed on the line by utility staff working from the ground with a telescopic perch.

A

B

C

The functional aspects were tackled first and various solutions were envisioned and tested for the clamp system to adapt to the diameter of the cable. The product being designed for mass production in injection molding, prototypes were cast in high impact, high-temperature polyurethane and epoxy resins, using the projected form factor and assembly solutions.

A left wing just released from the mold, before finishing. Note how the texture portrays well injection molding / sideview with wings open / internal view of the clamp bay. Despite the apparent complexity, this system uses only four different parts, including two for the induction clamp housing.

Functional prototypes for harsh environments are very interesting projects. While conveying the look-and-feel of the final product, their properties must also be close to the final materials, so results of functional verifications can be trusted. That involves selecting the right resin for each application, and carefully controlling casting and curing conditions.