This enclosure was designed to house a range of mid-size portable field instruments NDB Technologies had developed over many years for diverse applications, and that bore no resemblance to one another. These were specialized instruments and the annual sales were steady but not in numbers to justify investing in an injection mold. Or so it seemed.

The cost of machining each of the existing housings, if the quantities were to augment, would eventually compare with the initial cost of having an injection mold made. So the idea was to design a platform of a few injection-molded enclosures that would each accomodate a number of the instruments in the actual offering. That modular approach allowed to justify the financial aspect by combining all the instrument sales quantities, and provided an initial template for future developments as well. The largest board outline, top and bottom clearance were already determined, as well as the blank areas that allowed drillings in the side walls. This would greatly help future layouts, choosing connectors, and so on.

The housing was intentionally designed with limited molded-in features, and provided options for easy secondary operations to be performed in-house so instruments could be built on order. Another important effect of these choices was to create an identity around NDB’s family of products.

The modular approach extended to internal features like the battery bay, where a specific number of battery clips were wired and installed according to an instrument’s specific power requirements. The batteries being rechargeable this was transparent to the users and the batteries could be replaced during routine servicing by unscrewing the watertight rear door.

The user interface was composed of a small LCD screen and a membrane-switch which basic template allowed for up to 9 large-size buttons. The color schemes were done in accordance with NDB’s “look and feel”, with a combination of contrasting orange/blue scheme, enhancing visibility. The pictograms used were also standardized so the indicators of similar functions would remain consistent across the company’s products.

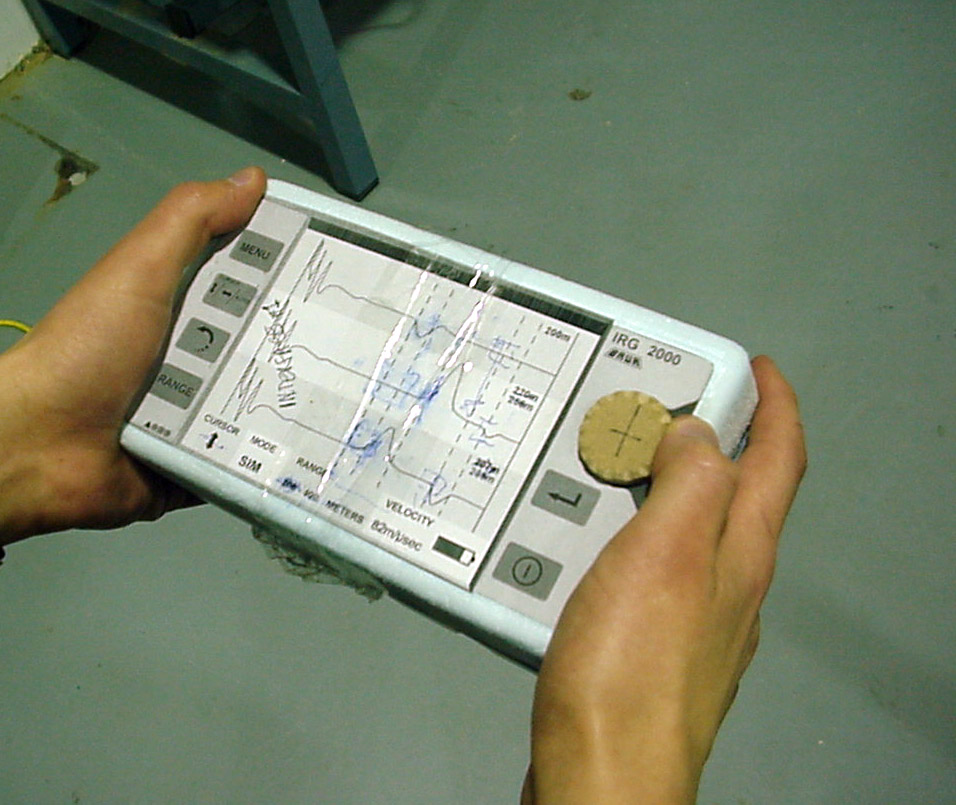

The housing’s modular approach allowed later expansion by creating a new faceplate based on the specific needs of a new project, without having to create an entirely new enclosure. An example of an alternate choice was the IRG2000, a powerline diagnostics instrument developed for Baur in Austria. It required a more elaborate graphic interface, with a means of navigating various menus while holding the instrument. The orientation was changed to horizontal, and a clickable knob was chosen to ease operation.

Prototypes are not always expensive!

This illustrates how a bit of forethought can go a long way. Projects seemingly out of reach may actually make good business sense much earlier than expected, when carefully planned and iteratively executed.